Intelligent Bolt

INTELLIGENT BOLTS

Concept of System

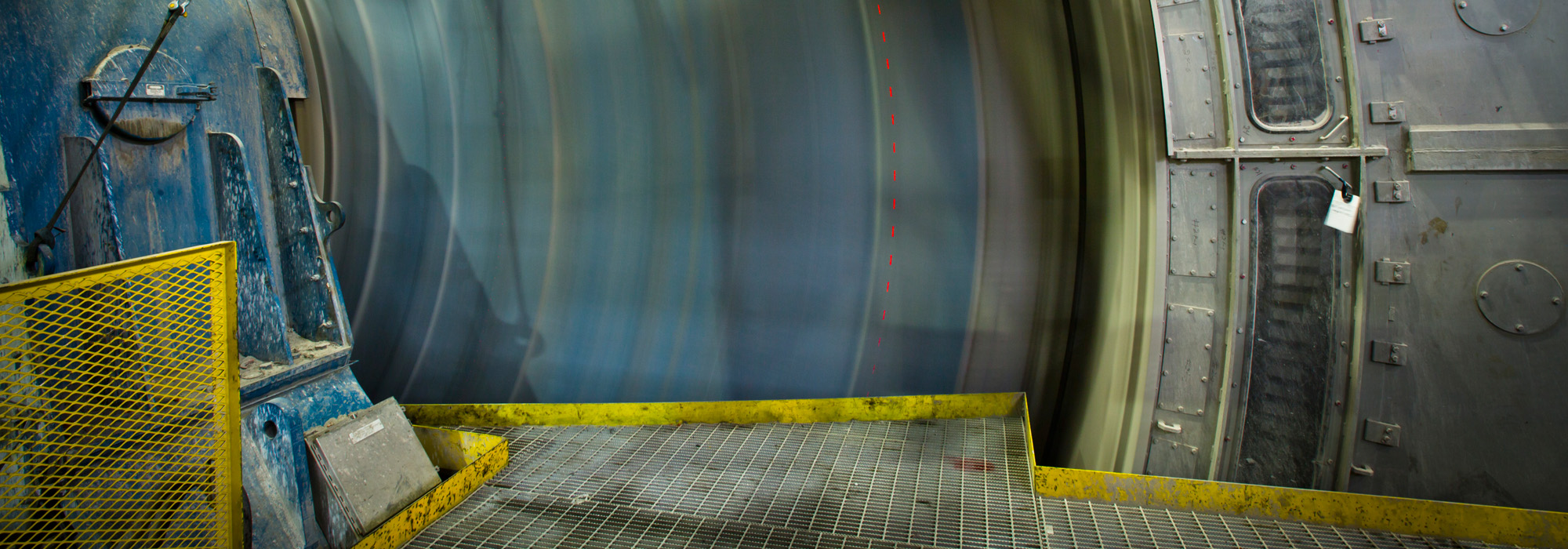

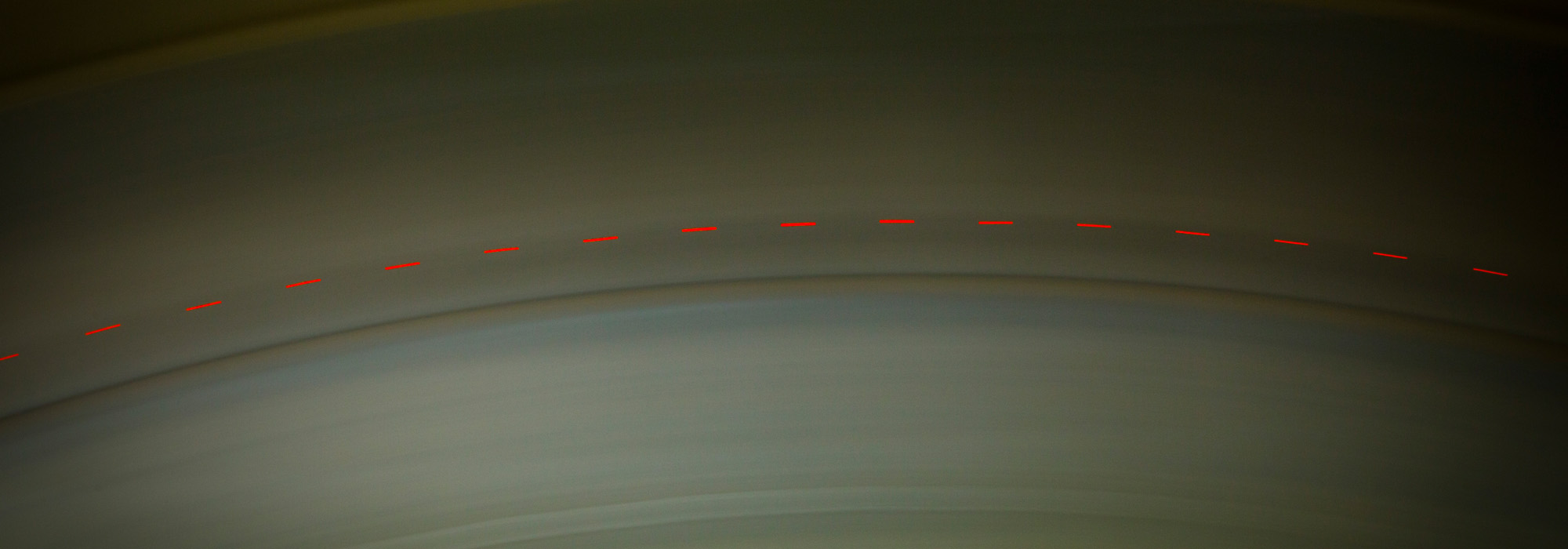

The Intelligent Bolt is a wear indicator bolt that provides mill operators with a direct measure of how the liners are wearing via an indicator light on the outside of the mill. When triggered by wear at a singular pre-set point, a LED set into the end of the Intelligent Bolt will flash for up to 48 hours.

The Intelligent Bolt is customized to the specifications of each mill and liner design, and should be positioned in high wear areas and designed in accordance with wear prediction requirements.

MILL AVAILABILITY

A correctly configured array of Intelligent Bolts will provide mill operators with visual confirmation of both liner wear and the rate of wear while the mill is running. This can reduce the need to shut down the mill in order to measure the liner wear, increasing mill availability and assisting with shutdown prediction and the optimization of reline planning.

REDUCTION OF SAFETY RISKS

Anytime a liner inspection is required, safety risks are introduced. The mixing of people and plant necessitates the use of extensive procedures and protocols to manage the risks associated with entering the mill. The use of Intelligent Bolts can reduce the need to enter the mill, thereby reducing the risks associated with mill entry.

TROUBLESHOOTING

Grinding mills typically experience accelerated liner wear in the high-wear areas of the mill, potentially resulting in structural mill damage. By utilizing Intelligent Bolts in these high-wear areas, the risk of sustaining permanent mill damage can be eliminated.